ANAEROBIC TECHNOLOGIES

CONVERT ORGANIC REFUSE WASTE TO VALUED

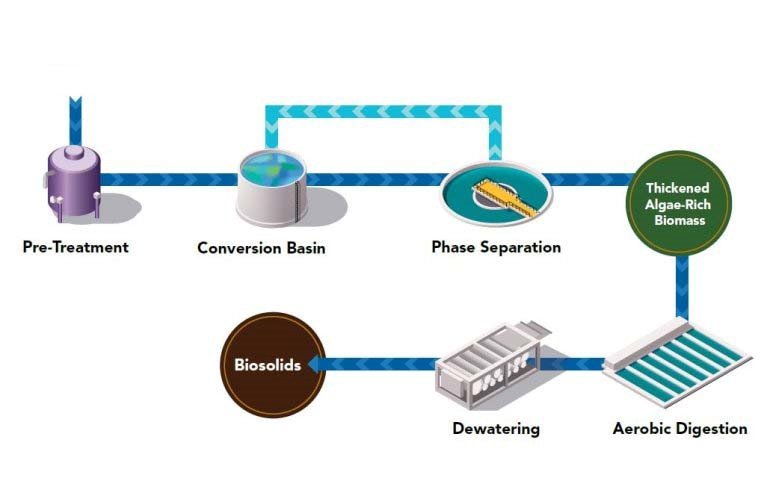

Aerobic treatment is a biological process that uses oxygen to break down organic matter and remove other pollutants like nitrogen and phosphorus. It converts organic matter into carbon dioxide and new biomass. During aerobic treatment, oxygen is continuously required so forced air from an air blower or compressor is mixed with the wastewater. The aerobic bacteria feed on the waste in this water and aerobic treatment takes place.

ADVANCED ANAEROBIC TECHNOLOGIES TO MAXIMIZE VALUE

Aerobic treatment is used to achieve maximum degradation while meeting the strict regulations set by environmental agencies regarding what is released into the air, ground, or water. Aerobic treatment systems offer a number of benefits:

• They play an important role in the wastewater treatment process ensuring that wastewater can be discharged safely in order for companies to meet strict environmental requirements

• The stabilized resulting sludge is odor free and makes an excellent fertilizer

• The operation is relatively simple.

INLET SCREEN

In the preliminary treatment the wastewater is screened (usually 3mm) removing inorganic solids that would otherwise buildup over time and need removal and cause issues with downstream processes. The collected screenings can be removed to the garbage disposal or incineration. The screened influent then enters the Aerobic Sludge Digester tank(s).

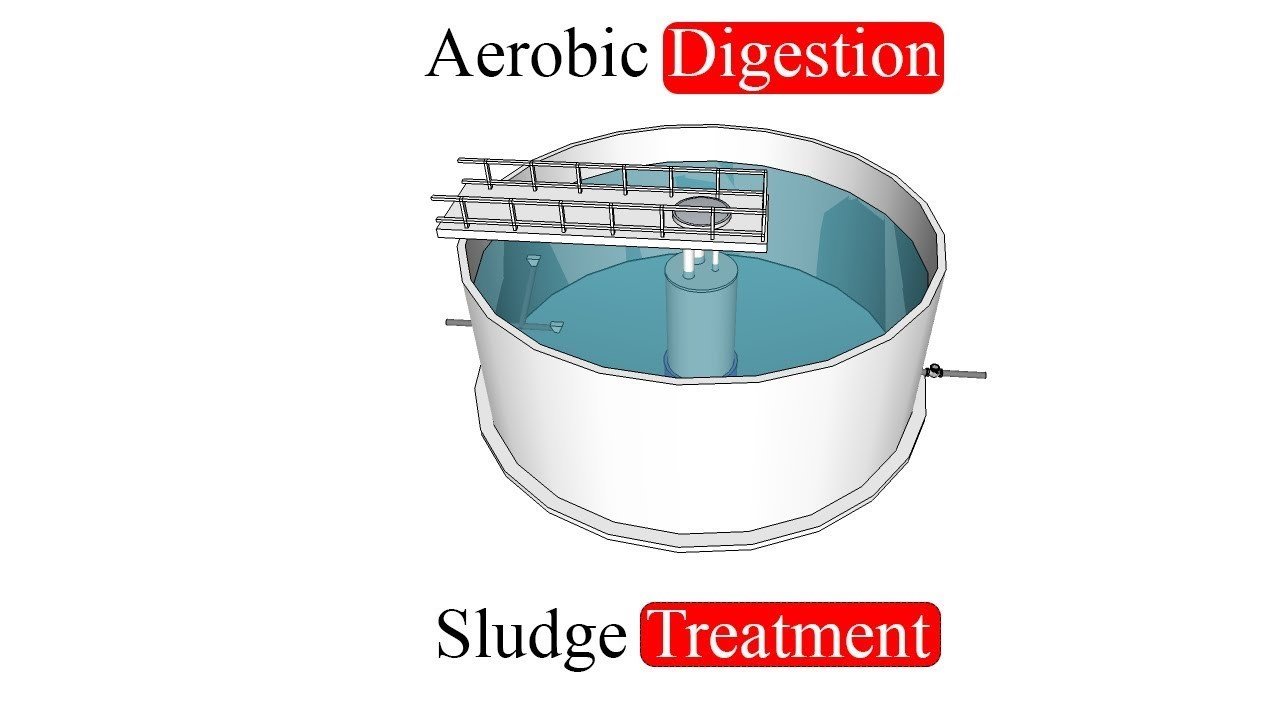

AEROBIC SLUDGE DIGESTER

The Aerobic Sludge Digester employs an aerated activated sludge process employing long Sludge Retention Times (SRT). The long SRT’s under extended aeration conditions allow for a highly stable process. The result is a stabilized and thickened waste activated sludge product that is not offensive and easy to handle. The sludge levels will be measured daily and the excess

wasted tothe sludge drying bed as necessary.

Here the wastewater is biologically purified by microorganisms that make up the aerobic activated sludge. The oxygen needed for the degradation process is brought into the water by fine bubble membrane aerators. For this process, an aeration blower pumps atmospheric air into the aerobic sludge digester. The air is pressed through the small pores of the membranes and is distributed in the wastewater as fine bubbles. The necessary

oxygen dissolves in the water and provides total mixing. This way activated sludge receives oxygen and nutrients by way of constant circulation and contact time. The holding tank for this process will be a minimum of 2 days retention, and will also behave as a flow equalization tank allowing a set hourly feed rate to the next step of the process – Bioreactors.

BIOREACTORS

The Wastewater component (mostly free of sludge) will be fed at an hourly rate to the Bioreactors for further treatment. The Bioreactors will remove remaining

nutrients, organics, and nitrogen from the wastewater. Any sludge and suspended solids will then be settled from the wastewater via the final clarifier. After clarification, the wastewater will undergo sanitization in a chlorine contact tank. The final effluent will be fit for discharge to the Environment.

The Bioreactors tank are fitted with a specialized Fixed- Film Media. The fixed film media provides an ideal surface area for the bacteria, responsible for removing contaminants from the wastewater, to live upon. Fine bubble aeration is installed under the media and provides the needed oxygen for the bacteria (as well as circulation of the tanks).

CLARIFICATION & DISCHARGE

After the Bioreactors, the activated sludge and other suspended solids are separated from the clear water under still conditions within a final clarifier. The settled sludge is sent back to the Sludge Digester. The clarifier, in turn, feeds the treated water to a contact storage tank where chlorine is added to sanitize the treated wastewater (for public health & safety).

SLUDGE DRYING BED

Here the excess stabilizes sludge is wasted to the drying bed where the sludge is dried. Once dried the sludge is a fraction of its former mass. A sludge drying bed provides a low-tech and economic solution for sludge dewatering. The excess sludge is periodically drained from the aerobic sludge digester and spread over the drying bed. The water passes through the sand bed leaving behind the sludge. The sludge left behind is then left to dry and then raked from the sand surface. The water that passes through the sand is directed back to the aerobic sludge digester inlet. The dried sludge is odorless and can be disposed of by landfill, incineration, and even for reuse application such as soil conditioner.